A flue lining in a masonry chimney is defined as “A clay, ceramic, or metal conduit installed inside of a chimney, intended to contain the combustion products, direct them to the outside atmosphere, and protect the chimney walls from heat and corrosion.” Although building codes vary from one state or locality to another, the installation of flue lining has been recommended since the early part of this century, and indeed most fire codes now mandate liners.

Liners in chimneys serve three main functions:

1) The liner protects the house from heat transfer to combustibles. In the NBS tests, unlined chimneys allowed heat to move through the chimney so rapidly that the adjacent woodwork caught fire in only 3 1/2 hours.

2) Liners protect the masonry from the corrosive byproducts of combustion. In the tests it was determined that if the flue gases were allowed to penetrate to the brick and mortar, the result would be a reduction in the usable life of the chimney. The flue gases are acidic in nature and literally eat away at the mortar joints from inside the chimney. As the mortar joints erode, heat transfers more rapidly to the nearby combustibles and dangerous gases such as carbon monoxide can leak into the living areas of the home.

3) Liners provide a correctly sized flue for optimum efficiency of appliances. Modern wood stoves and gas or oil furnaces require a correctly sized flue to perform properly. The chimney is responsible for not only allowing the products of combustion a passage out of the house, but the draft generated by the chimney also supplies the combustion air to the appliance. An incorrectly sized liner can lead to excessive creosote buildup in wood burning stoves, and the production of carbon monoxide with conventional fuels.

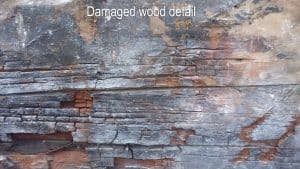

Here we see burned siding and framing on a home in NE Portland, photos taken during a chimney rebuild.